Learn more about how Syscor equipment can monitor your application. Click a heading below to expand.

Over the lifetime of an internal or external floating roof tank, events can arise that lead to integrity failure of the floating roof. Syscor has a solution to monitor and detect these events so that the tank operator has time to fix the problem before it takes the tank out of service.

Over the lifetime of an internal or external floating roof tank, events can arise that lead to integrity failure of the floating roof. Syscor has a solution to monitor and detect these events so that the tank operator has time to fix the problem before it takes the tank out of service.

A Syscor floating roof monitoring system would look a lot like this two-tank example:

Example explained: On each tank are three deck-mounted Syscor FR-Tracker 2.0 devices. They use the radio standard WirelessHART to communicate in a mesh network with each other. The metal walls of the tank prevent the deck-mounted devices' radio signals from reaching the WirelessHART Gateway, so a repeater is mounted near the ladder to form a radio pathway. At the WirelessHART Gateway is the physical access point to all of the data collected from devices in the mesh network. The access protocol is Modbus TCP or Modbus RTU. This is conveniently linkable to a DCS/SCADA system.

Deck-Mount Devices:

Repeaters:

WirelessHART Gateway:

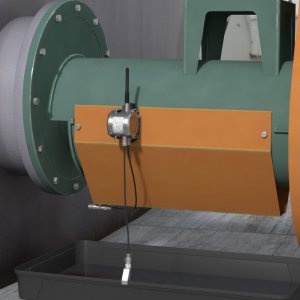

Syscor has a solution to monitor and detect mixer leak events, giving the operator time to fix the problem in the early stages before it causes a large maintenance or environmental concern.

Syscor has a solution to monitor and detect mixer leak events, giving the operator time to fix the problem in the early stages before it causes a large maintenance or environmental concern.

Syscor's application is shown in this storage tank with triple side-entry mixers example:

Example explained: On each mixer is an HC-Tracker device. They use the radio standard WirelessHART to communicate in a mesh network with each other, the HC-Tracker at the back forms a radio path to the WirelessHART Gateway through its closest neighbor. At the WirelessHART Gateway is the physical access point to all of the data collected from the devices in the mesh network. The access protocol is modbus TCP or Modbus RTU. This is conveniently linkable to a DCS/SCADA system.

Mixer Monitoring Devices:

WirelessHART Gateway:

![]() Pipe flanges may spring a leak due to a variety of causes, from rapid temperature fluctuations to unevenly tightened bolts. Leaks can be a recurring problem for many operators especially in places that avoid in-person inspections. Syscor has a solution to monitor and detect pipe flange leak events giving the operator time to fix the problem before it becomes a large maintenance or environmental concern.

Pipe flanges may spring a leak due to a variety of causes, from rapid temperature fluctuations to unevenly tightened bolts. Leaks can be a recurring problem for many operators especially in places that avoid in-person inspections. Syscor has a solution to monitor and detect pipe flange leak events giving the operator time to fix the problem before it becomes a large maintenance or environmental concern.

Syscor's application is shown in this pipe field example:

Example explained: On each pipe flange is a HC-Tracker device. They use the radio standard WirelessHART to communicate in a mesh network with each other. At the WirelessHART Gateway is the physical access point to all of the data collected from the devices in the mesh network. The access protocol is modbus TCP or Modbus RTU. This is conveniently likable to a DCS/SCADA system.

Flange Monitoring Devices:

WirelessHART Gateway:

![]() For sumps that collect water and/or hydrocarbon product spills, it is important to know when they start to fill with water, how full they are, and if any hydrocarbon product found its way inside, which would indicate a leak somewhere nearby.

For sumps that collect water and/or hydrocarbon product spills, it is important to know when they start to fill with water, how full they are, and if any hydrocarbon product found its way inside, which would indicate a leak somewhere nearby.

A Syscor sump monitoring system would look a lot like this 2 sump example:

Example explained: In each sump are two Syscor HCDW Hydrocarbon Detector Probes. These probes measure temperature, water height, acceleration, and hydrocarbon presence. They interface with a PCU-X01 Sensor Hub mounted up to 33ft/10m away. The Sensor Hub communicates using the mesh radio protocol WirelessHART with a Gateway located in an electrical shed nearby. The Gateway is the physical access point to all of the data collected from the devices in the mesh network. The access protocol is Modbus TCP or Modbus RTU. This is conveniently linkable to a DCS/SCADA system.

Sump-Mount Devices:

WirelessHART Gateway:

Underground pipelines, when they leak, tend to do so around a flange. Hydrocarbon product can seep into the environment for years before eventually being detected on the surface (sometimes by members of the general public). Syscor offers a subterranean monitoring solution that can be located at suspected trouble spots along a pipeline, giving the operator time to fix the problem before it becomes a large environmental concern.

Underground pipelines, when they leak, tend to do so around a flange. Hydrocarbon product can seep into the environment for years before eventually being detected on the surface (sometimes by members of the general public). Syscor offers a subterranean monitoring solution that can be located at suspected trouble spots along a pipeline, giving the operator time to fix the problem before it becomes a large environmental concern.

Syscor offers two different systems applicable to this application as shown in this example:

Example explained: Excavated wells are situated nearby three at-risk pipeline flanges. Each well contains Syscor HCD Hydrocarbon Detector Probes optionally wrapped in a Polyfluoro wicking sleeve. At the top of the pipe (aboveground) sits either the WirelessHART connected PCU-X01 or the cellular connected Syscor ELDS.

Pipeline Monitoring Devices:

WirelessHART Gateway:

Hydrocarbon leaks may enter the watershed. Watershed entry will spread a spill further, faster. Syscor’s water monitoring solution enables leak detection in streams, rivers, lakes or oceans.

Hydrocarbon leaks may enter the watershed. Watershed entry will spread a spill further, faster. Syscor’s water monitoring solution enables leak detection in streams, rivers, lakes or oceans.

A Syscor water monitoring system would look a lot like this stream example:

Example explained: Well tubing is either embedded in the bed or suspended from a structure over the water. Each well contains up to two Syscor Hydrocarbon Detectors. At the top of the tubing sits either the WirelessHART connected PCU-X01 or the cellular connected Syscor ELDS.

PCU-X01 Sensor Hub with attached HCD/W Probe(s):

WirelessHART Gateway: